Ilankai Tamil Sangam

Association of Tamils of Sri Lanka in the USA

Published by Sangam.org

by Industrial Minerals, October 13 2011

|

An SLFP politician made an allegation in 1989 that a ton of the ore which at that time was fetching 120 US dollars in the world market was being sold at a mere 50 US dollars and that no tender procedure had been followed in the sales. Somebody, in between, was making a cool 2.5 million US dollars every year. |

Mining of a rich minsands deposit in north-eastern Sri Lanka is to be ramped up to pre-war levels of 100-125m. tonnes with $500m. investments in new plant and machinery. State-owned Lanka Mineral Sands Ltd., which owns and operates the Pulmoddai mine, is keen on a joint venture with an international partner to make value-added products...

Tamil Guardian 2005 article about Pulmoddai mining & its implications: "Acrimony Brews Again Over Pulmoddai Sands"

Tussle for Titanium by Sivaram 1997

Industrial zone to be set up surrounding Pulmoddai Mineral Sand Company in eastern Sri Lanka

Wed, Nov 16, 2011, ColomboPage News Desk, Sri Lanka.

Nov 16, Colombo: The Sri Lankan government considering to set up an industrial zone in a 500 acre land surrounding the Pulmoddai Mineral Sands Company.

The State Resources and Enterprise Development Ministry is currently in engaged in drawing up the plan for the project.

State Resources and Enterprise Development Minister Dayasritha Tissera has said that the plan once prepared would be handed over to President Mahinda Rajapaksa. The project would be implemented once President's approval is received.

It has also been planned to set up new machinery worth US$ 70 million in the Pulmoddai Mineral Sands Company to increase its production capacity.

According to Tissera, the Mineral Sands Company had recorded a profit last year and is now aiming at earning revenue of Rs. 7 billion. The enterprise had recorded a Rs. 85 million loss in 2006.

The Corporation currently exports mineral sand to Russia, Japan, US and the UK and is to venture into value added export products.

------------------------------------------------------------------------

Sri Lanka's Pulmoddai mineral sands plant resumes production

by Siobhan Lismore, Industrial Minerals, April 7, 2011

Government pushes for investment into minsands, talks of opening vein quartz

The Pulmoddai Minearl Sands Factory in Sri Lanka has resumed production, according to press reports.

The Sri Lanka Sunday Observer said that the plant had resumed production after being down due to the conflict between the government and the Tamil Tigers rebel group.

Mininig in the Pulmoddai region, 52 km north of Trincomalee, came to a halt in the late nineties following the sinking by...

-------------------------------------------------------------------

By L.S. Ananda WEDAARACHCHI, Sunday Observer, Colombo, October 23, 2011

Lanka Mineral Sands Ltd., Managing Director Dilshan Goonasekera |

Secretary - State Resources and Enterprise Development Ministry Dr. Willy Gamage |

The mineral sands industry in the eastern coast is expanding, Lanka Mineral Sands Limited Managing Director, Dishan Goonasekera said.

The mineral sands deposit is one of the most treasured natural resources in the country. It was discovered by Sri Lankan scientists in the 1950's.

The mineral sand factory at Pulmoddai set up in 1970 was destroyed by the LTTE. The factory has been reactivated, he said.

|

State Resources and Enterprise Development Ministry Secretary, Dr. Willy Gamage and Lanka Mineral Sands Ltd., Chairman, Dishan Goonasekera were interviewed by the Sunday Observer recently.

Excerpts of the interview.

Q: Lanka Mineral Sands Ltd., has been transformed into a profit making venture under the guidance of State Resources and Enterprise Development Ministry within a period of two years. As Ministry Secretary would you like to explain the secret behind this success?

|

Collecting mineral sand |

Pulmoddai mineral sand factory |

A: The company earned a profit of Rs. 678 million last year. Dividends of Rs. 572 million was credited to the Treasury. We have targeted a profit of Rs. 8,400 million for 2011-2012. The targeted production for the year will be 112,904 mt. Proper planing and the team work is the secret behind this achievement.

Q: When did mineral sand production commence in Sri Lanka?

A: The Mineral Sand Corporation was set up in 1960 under the Industrial Act of 1957. The Japanese government provided the technical and scientific assistance for the project.

Even the first shipment of Ilmenite was imported by a Japanese company named Ishihara Sino Kaisa in 1962.

The Asian Development Bank provided assistance in 1978 for the development of the industry.

While the industry was in rapid progress earning billions of foreign exchange through the export of mineral sand the LTTE brought the operation of the factory to a standstill in 1983. When it remained closed for nearly thirty years there was an attempt to sell the factory during the UNP regime in 2001. The Ministry of State Resources and Enterprise Development was set up primarily to reactivate the defunct state enterprises.

Q: In your capacity as Chairman of the company could you explain the future plans to expand the industry.

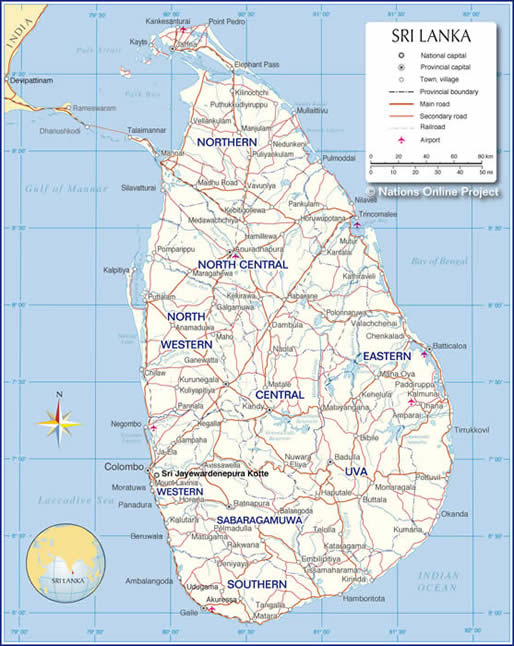

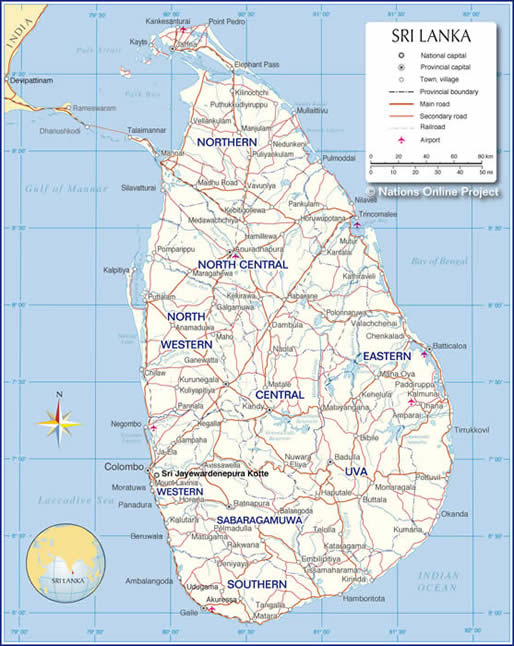

A: Mineral sand deposits are found along the eastern coastal belt from Mulaitivu to Pulmoddai and from there to Kotuwakambi.

This is one of the most treasured natural resources of Sri Lanka.

At present a plan for the scientific and systematic development of the industry is being implemented under the guidance of State Resources and Enterprise Development Minister Dayashrita Tissera and ministry secretary Dr. Willy Gamage. Mineral sand is a hundred percent export oriented product.

There is a big demand for our mineral sand from industrial countries. The value of mineral sand had increased sharply during the last couple of years.

The price of a MT of Ilmenite has increased by 700 percent during the last two years.

The Pulmoddai factory will be modernised under the development plan. A new plant will be commissioned within a period of four years. A team of local and foreign experts had been assigned to make a feasibility report on the new plant.

Modification and upgrading of the present plant will begin in November and will be completed within 18 months.

Q: Could you explain the production process of mineral sand?

A: Sea waves bring mineral sand from the sea bed to the beach. Truck loads of sea sand are brought to the mineral sand factory where mineral sand are separated from sea sand. It is a highly sophisticated process. Ilmenite Rutile, Magnatile, Serkon are produced at the Pulmoddai factory.

Q: Can you explain the demand for mineral sand by industrialised countries?

A: Mineral Sands such as Ilmenite, Rutile, Serkone, Gakone, Magnetite are used as a raw material to manufacture paints, paper, ceramic and medicinal products. Titanium Dioxide-TIO-2 is manufactured using Ilmenite.

Q: What are the other leading countries that produce mineral sand?

A: Mineral sands deposits are available in USA, Australia and China where mineral sand content in sea sand is around three percent to five percent while it is more than 80 percent in Sri Lanka sea sand.

What Sri Lanka needs is an advanced technology to develop the industry. Negotiations in this regard are held with regional countries, Europe and USA.

Q: Why don't you go for value added products while exporting raw materials to industrialised countries?

A: We could fulfil our targets by setting up the proposed second factory.

We have already held discussions in this regard with countries where the mineral sand industry is developed.

--------------------------------------------------------------------------------------

Sri Lanka to Manufacture Nano Titanium Dioxide from Pulmoddai Mineral Sands

By Ramani Kangaraarachchi, 04th May 2010, www.dailynews.lk, nka can look forward to manufacturing its own nano titanium dioxide from Pulmoddai mineral sands deposits.

nka can look forward to manufacturing its own nano titanium dioxide from Pulmoddai mineral sands deposits.

© 1996-2024 Ilankai Tamil Sangam, USA, Inc.